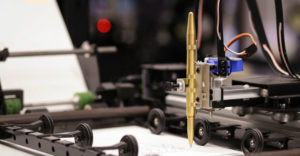

When Dave Asiala, Dow Chemical’s sharedservices IT director, is talking about his company’sRFID (radio frequency identification) initiatives and wants listeners to have an “Aha” moment, he tells them about Dow AgroSciences’ use ofRFID tags in its in-ground Sentricon Termite ColonyElimination System.

“Essentially these are bait traps that areunderground,” Asiala says. “Over the last couple of years, we havemodified the product to include a passive RFID tagthat is triggered when the bait is eaten. Now theservice provider has a much easier way of reading whentraps have been activated — all he has to do is wavethe wand over the ground to see if the bait has beentaken.”

Asiala likes using this example because it illustratesthe many uses to which RFID technology can be adapted.Typically — and as is the case with Dow Chemical –RFID technology is first deployed as an internalproductivity play.

As the technology becomes morerobust, though, he said, it exposes not only newopportunities in the supply chain, but also ways toimprove other products and services. Following areexcerpts from CRM Buyer’s exclusive interview with Asiala aboutthe company’s RFID strategy.

CRM Buyer: Can you tell me about some more interesting uses for RFID?

Dave Asiala:

Well, one use is with our rail cars. Rail carshave been using some form of passive RFID technologyfor the last 15 years, usually in a “last seen”function — that is, it can track where the car lastregistered in the system. We own about 26,000, and haveoutfitted two fleets of rail cars and are outfittingtwo more with a GPS (Global Positioning System) device and an RFID sensor unit tohelp us monitor the 20 percent of shipments that arehazardous materials.

What we are doing is augmentingthe last seen capability with real-time pollingcapability. In case of an accident, we want to useinformation like the environmental condition of thecar to help first responders.

Our current safety performance with our assets is99.97 percent incident-free. The technology we areputting in now will take us beyond that.

There are smaller-use cases too. For instance, DowChemical employees have badges equipped with passiveRFID tags. The readers at our facilities around theworld will grant access based on the user’s profile.We can use the badge globally. I used mine in Brazilrecently, for example.

Other examples include pipelines that send out remotesignals when repairs are needed, and equippingintermodal shipping containers with active RFID tags.

CRM Buyer: How does Dow Chemical decide which projects to initiate?

Asiala:

Rather than going at it piecemeal, we have puttogether a strategy around the use of RFID and GPStechnologies so they can make a difference in ourorganization. This is a multi-generation plan — welooked at, say, 450 ideas and narrowed that number to50, and then we took the top ten of those ideas and putthem in the first generation of our implementationplan.

We have a very strong ROI mentality — when a divisionor unit decides to make improvements in our IT or workprocesses, we have to compete for dollars. We are veryproud of the fact that the program is able to competefor and receive funding.

CRM Buyer: How does the budgeting process work?

Asiala:

Well, roughly, we have long-term spending plans andannual investment plans. Our company will determinehow much money will be spent based on the tangiblebenefits the project will bring to the bottom line.

The soft benefits, such as safety and security, wedon’t even count. A NPV (net present value) is one ofthe most significant factors that help us decide inwhat technologies to invest.

That doesn’t mean everysingle project we do adds value — some are lossleaders. But by looking at our program as a whole, wegive ourselves the ability to make these strategicdecisions.

CRM Buyer: What has been the ROI (return on investment) for some of these projects you’ve described?

Asiala:

We don’t share ROI numbers. We do have thresholdsand hurdles that we have to meet, such as a time tozero cash flow hurdle or an NPV return on a lifecycle,which we can calculate based on three, five or tenyears. And if the return is not meeting expectationhalf way through the cycle, we will change the plan.